You've finished your cold room installation, rooms are set to be stocked, and you're ready to do so.

However, Atlas Modern Engineering gives you one critical benefit before doing anything- cold room thermal image scanning.

What exactly is cold room thermal imaging?

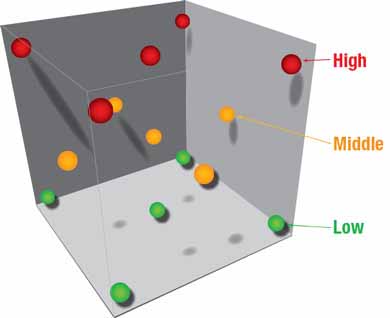

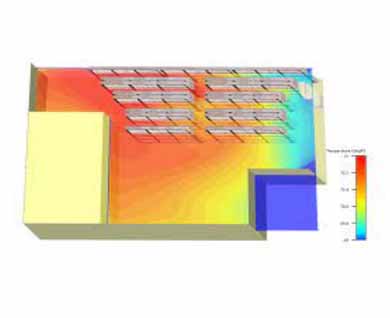

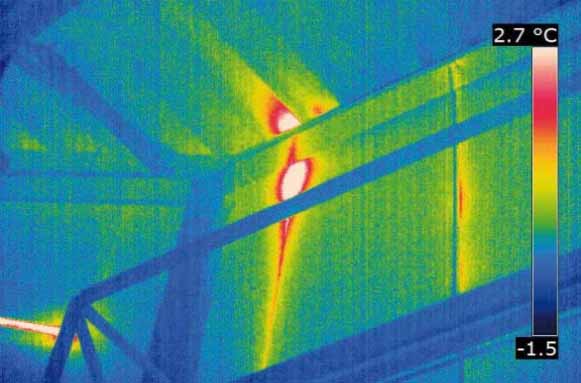

Thermal imaging and thermography are both techniques used in cold rooms, freezers, and temperature-controlled environments for detecting heat loss. Atlas Modern Engineering Services & Trading L.L.C thermal imaging scan can identify a potential thermal leak in the thermal panel/connection points area. One-tenth of a degree is as precise as the thermal pictures. It is a reliable way of safeguarding your business's assets and provides you with a sense of security.

Huge walk-in freezers are often installed by enterprises that need to keep large quantities of products at temperatures far below the freezing point of water. Large freezers can store entire rooms full of food items such as frozen vegetables, fruit, and bread at near-freezing temperatures. The only negative aspect is that it takes a lot of energy to cool. The truth is no heat must be allowed to seep into the building. Atlas Modern Engineering use thermal imaging cameras to check the insulating material in the freezer to ensure it is effective. Essentially, checking big commercial refrigeration systems such as walk-in freezers and cold rooms is like building insulation examinations; it's only when we have a ten-degree temperature difference between interior and outside air that leaks are located.

Atlas Modern Engineering Services & Trading L.L.C Thermal Imaging Aids in the Detection, Troubleshooting, and Repair of Cold room Problems, Preventing Expensive Shutdowns and Outages.

We do cold room thermal imaging surveys without interfering with your normal activities. Our thermographic scans provide numerous advantages, including minimal downtime, which allows your operations to run at peak efficiency, and cost savings by utilizing an exceptionally prompt and efficient screening approach .Our thermal imaging assessments for cold room insulation offer value by:

- Detecting high-cost energy losses due to warm air infiltration into the cold room

- Identify probable moisture intrusion and dangerous ice formation.

- Determine the sources of ice develop on cold room walls and roofs.

- Evaluate the various heat sources inside the cold room

- Inspect a new cold room or freezer to ensure it is constructed properly and is adequately insulated.

What are the advantages of cold room thermal imaging for the user?

All effects of vapor, air leakage, and heat transfer create additional energy consumption and limit the shelf life of products. There's also the issue of safety to consider. Condensation and ice are caused by air escape and heat transfer. This is not an intelligent mix in high-traffic areas, as it could result in a slip and fall hazard for your personnel as well as a lack of control over lifting equipment. Use Atlas Modern Engineering thermal scan to prevent these difficulties to ensure your cold room facility is working securely and effectively.

What are the advantages of cold room thermal imaging for the installer?

A visual scan performed by Atlas Modern Engineering before the rooms are filled with products helps discover a potential problem in the installation or panel system before storing your inventory. The thermal imaging scan can be performed while the room is filled, but there is a fear of defamation if the fix is required during working hours in the facility, not to mention the danger of a site employee falling due to ice or dampness.

How effective Cold room thermal imaging adds value to your business.

With Atlas Modern Engineering you can be sure no air or vapor leak can affect your cold room storage. We employ cutting-edge infrared imaging technology to detect poor insulation and dangerous ice accumulation in cold room panels. We want to take rapid necessary actions to improve worker safety and lower maintenance costs. We'll track out the lost puzzle pieces and return them to you! Why partner with us to schedule thermal imaging?

- We Save your time. One of the advantages of thermal imaging is that it does not require any downtime. Our thermal scan inspection procedures ensure that your everyday activities are not disrupted.

- We instantly point up any existing flaws or problems and provide detailed reports within 24 hours of the assessment.

- We can develop trends by observing cold room and freezer panels regularly, which can be utilized to forecast equipment and panel breakdown. This vital information enables your preventative maintenance staff to complete upgrades and maintenance work during a "scheduled" window, rather than an unanticipated outage that results in revenue and productivity losses.

We detect cold room insulation issues before they turn into a disaster! Contact us today